Please contact us at support@phoenixenvironmentalsystems.com with any questions you have about our services or the technologies that you have seen on our site.

Frequently Asked Questions:

What does E85 mean? How does the US mandate ethanol usage?

What is a Plasma Conversion System?

Advantages of Plasma Converstion Systems

Other Benefits of Plasma Conversion Systems

What does E85 mean? How does the US mandate ethanol usage?

E85 is a mix of 85% ethanol and 15% gasoline and it can only be used in flex-fuel vehicles. It cannot be used in conventional engines, but E85 flex-fuel vehicles can run any fuel with 0 to 85% ethanol.

Since 2001, the EPA’s Renewable Fuel Standard has approved the 15% ethanol and 85% gasoline blend (E15) from the previous 10% blend (E10). According to the Energy Independence and Security Act of 2007, ethanol use will increase to 36 million gallons by 2022 (in 2007 it was 4.7 billion gallons) in the United States. By 2022 of which 60% of it must be ethanol from non-corn based ethanol.

A kilowatt-hour (kWh) is 1000 watts per hour. A watt-hour is usage over time, while a watt is usage at this instant. A 100-watt light bulb will use 0.1 kW per hour, calculated by multiplying the wattage by the number of hours (in this case one) and divided by 1000.

A kilowatt is 1,000 watts, and a megawatt is 1,000,000 watts.

If you only know the amps, you can multiply amps by volts to get the amount of watts in a household appliance.

What is a Plasma Conversion System?

The plasma conversion system provides a total solution to the problems of waste management. This is a general overview of the plasma conversion system that safely, efficiently and economically destroys wastes, no matter what form, and turns the waste into useful and valuable products. This system can efficiently process waste streams eliminating all waste that is not nuclear.

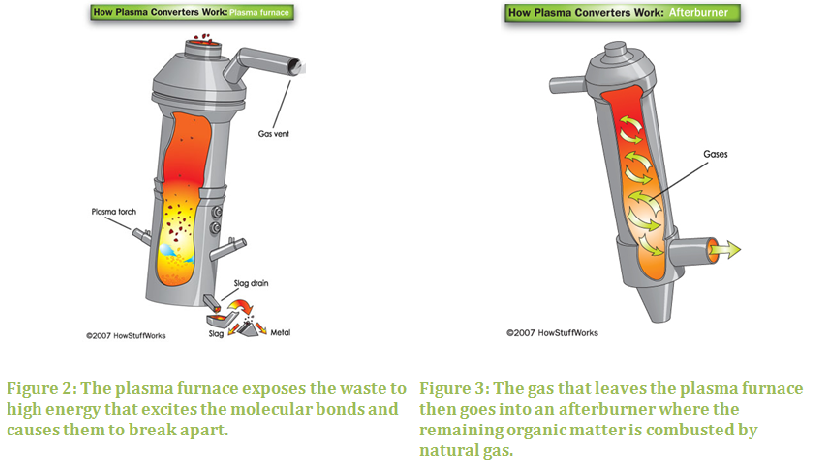

The plasma system is an electrically driven system which causes the molecular breakdown of matter. The energy that the waste is put under produces chemical decomposition or dissociation on a molecular scale until the waste reaches the level of the basic components (atoms). In doing so, the System protects the environment and helps to improve the public health and safety, vital to the ecosystem, the tourism industry and the local economy.

The plasma conversion system achieves closed-loop elemental recycling to safely and irreversibly destroy all industrial and agricultural waste which includes:

The plasma conversion system achieves closed-loop elemental recycling to safely and irreversibly destroy all industrial and agricultural waste which includes:

· organics and inorganics

· solids, liquids and gases

· hazardous and non-hazardous industrial waste

· e-waste (electronic waste)

· medical waste

· chemical industry waste

· Municipal Solid Waste (MSW)

and other special wastes while converting many of them into useful commodity products that can include metals and a synthesis-gas.

The plasma system melts and recovers metals for the metallurgical industry, and other non-organics such as glass, dirt, rock, resulting in an obsidian-like, glassy silicate compound.

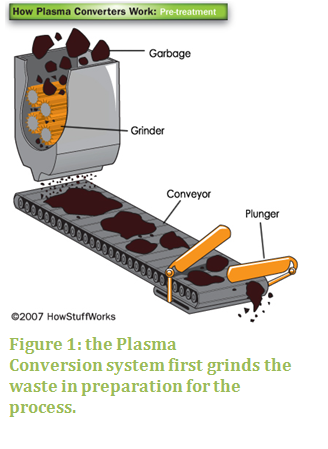

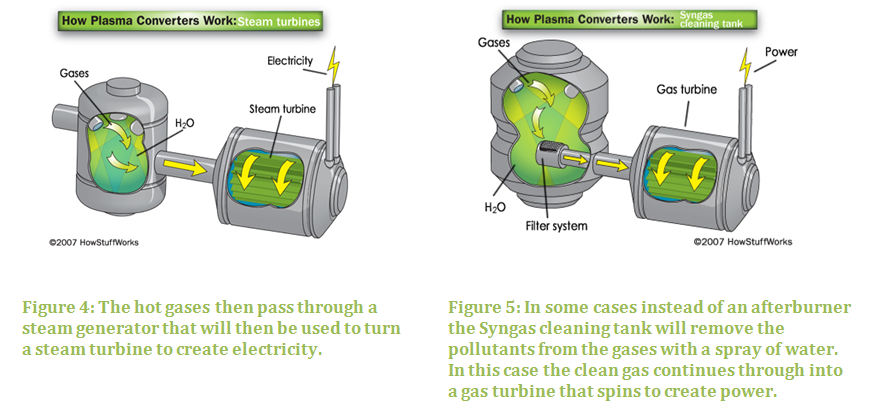

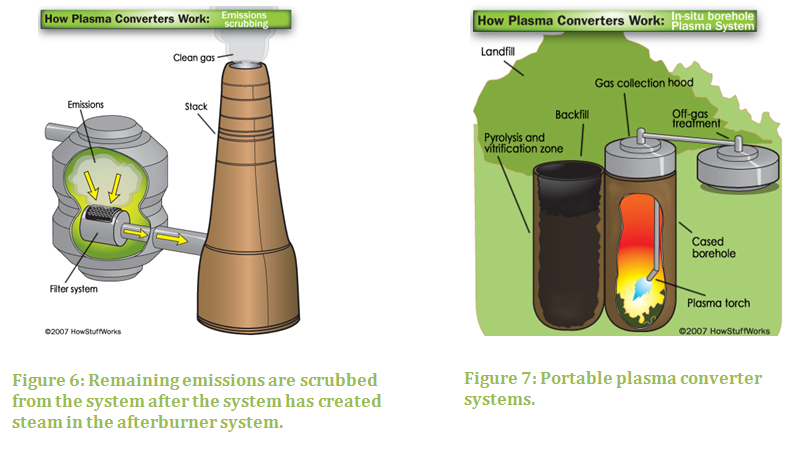

The following figures show how the plasma conversion system works through the different steps starting with figure 1.

Advantages of Using a Plasma System

1. Can process all waste material safely and economically, in any form:

· hazardous and nonhazardous wastes-solids, liquids, sludges and gases

· medical wastes industrial wastes including chemical solvents, greases, sludges, refinery by-products

· sanitary waste

· specialty wastes

2. Produce green non-dollar generated electricity.

3. Provide employment opportunities and training of local populace in new technical skills.

4. Closed-loop elemental recycling system processes wastes safely and economically in non-combustion, no smoke stack process without producing harmful, noxious emissions, effluents or residues.

5. Recycles wastes into marketable commodities such as materials for building and highway constructions. Materials previously regarded as waste are recycled and processed as feedstock to produce these commodities.

6. Improves public health and safety.

· Reduction of indiscriminate burning of waste.

· Reduction and elimination of untreated and non-sealed landfills thereby and will not produce the harm that arises from incinerators and landfills.

· Potential Reduction and elimination of endemic diseases such as Dengue fever and malaria that arise from mosquito breeding sources in landfills.

7. Greatly reduces cost and risks associated with waste generation producing positive cash flow and profits.

8. Meets and exceeds all U.S. EPA emission standards.

9. Systems are scalable, and can be used to just a few tones to hundreds of tons per day based on available feedstock.

10. System can be located adjacent to existing landfill.

11. Volumetric waste reduction for most solid wastes is approximately 300 to 1.

12. Combined Energy Efficiency (energy input versus output) is greater than 85%.

13. Recycling of landfills would reduce discharge of contaminants into the atmosphere and groundwater, such as carbon dioxide, sulphides, and pesticides.

14. Mining of existing landfill sites until fully emptied and reclamation of landfill sites producing green usage space.

15. Can operate continuously without many of the difficulties and costs that arise in other technologies when operated in the same manner.

16. Because the System is inherently safe, being electrically driven, unlike incinerators, its operation can be stopped immediately by shutting off the electricity.

17. The system is computer controlled, easy to use and operates at normal atmospheric pressure, very safely and quietly.

Other Benefits of Plasma Gasification:

Other Benefits of Plasma Gasification:

Plasma gasification has several byproducts that can be used as raw materials to create other products. The plasma system results in an ash while some other gasification processes create slag.

Slag is about 20% of the weight of the original waste and about 5% of the original volume. Depending on the system used slag takes different forms (air or water cooling systems). Slag comes out in a liquid form and one of the possible uses of slag is that it can be funneled into molds and used in construction material.

In the byproducts of the plasma systems any hazardous materials that had once been part of the system are inert and the materials are in no danger of dissolving out. Thus the materials are safe for the environment and the health of those that will have exposure to them.